With the development of modern industrial manufacturing industry, great changes have taken place in the development of disc special machine tools. Compared to ordinary machine tools, the number of electronic components is increasingly accurate. In the process of processing for the environment, air, power and other factors have relatively high requirements, but also easily affected by these factors, perhaps a certain indicator is not up to standard, or a small error in operation, will make a big difference in the product.

Installation position requirements

First of all, the location of the disc special machine tool installation should be far away from the vibration source, to avoid the influence of direct sunlight and thermal radiation, to avoid the influence of moisture and airflow. If there is a vibration source near the machine tool, an anti-vibration ditch should be set up around the machine tool. Otherwise, it will directly affect the machining accuracy and stability of the machine tool, and will make the electronic components in poor contact, failure, affecting the reliability of the machine tool. Conditional enterprises, as far as possible to use the location in an air-conditioned environment, and maintain a constant room temperature. The more expensive the machine tool, the more it should be used in the air-conditioned room to avoid unnecessary loss of accuracy.

Ambient temperature requirement

Due to the large difference between the north and the south of China, the requirements of the machine tool for the ambient temperature are relatively high, so in general, the electric box will be installed with exhaust fans or chiller to keep the working temperature of the electronic components, especially the central processor, constant or small temperature change. However, this is still not enough to guarantee the loss of accuracy of the machine tool during the processing, because the machine tool will produce excessive temperatures during the processing, which will lead to the reduction of the life of the control system components. The increase in temperature and humidity will also increase and bond the dust in the integrated circuit board, resulting in short circuit and machine tool failure. Therefore, it is best to ensure a constant environment around the machine tool. In addition to the temperature, it can not be placed in a place with corrosive gases, if the electronic components are corroded by corrosive gases resulting in short circuit of the system, then the serious consequences can be imagined.

Power requirements

Disk special machine tools need power to operate the equipment, and the general processing enterprises are often not only one equipment, multiple equipment, the power grid will fluctuate greatly when used at the same time, thus affecting the processing effect. Therefore, when installing, it is necessary to strictly control and select the power supply used, and only when the voltage fluctuation is controlled within a safe and stable range, can it not affect the normal operation of the machine tool processing and numerical control system.

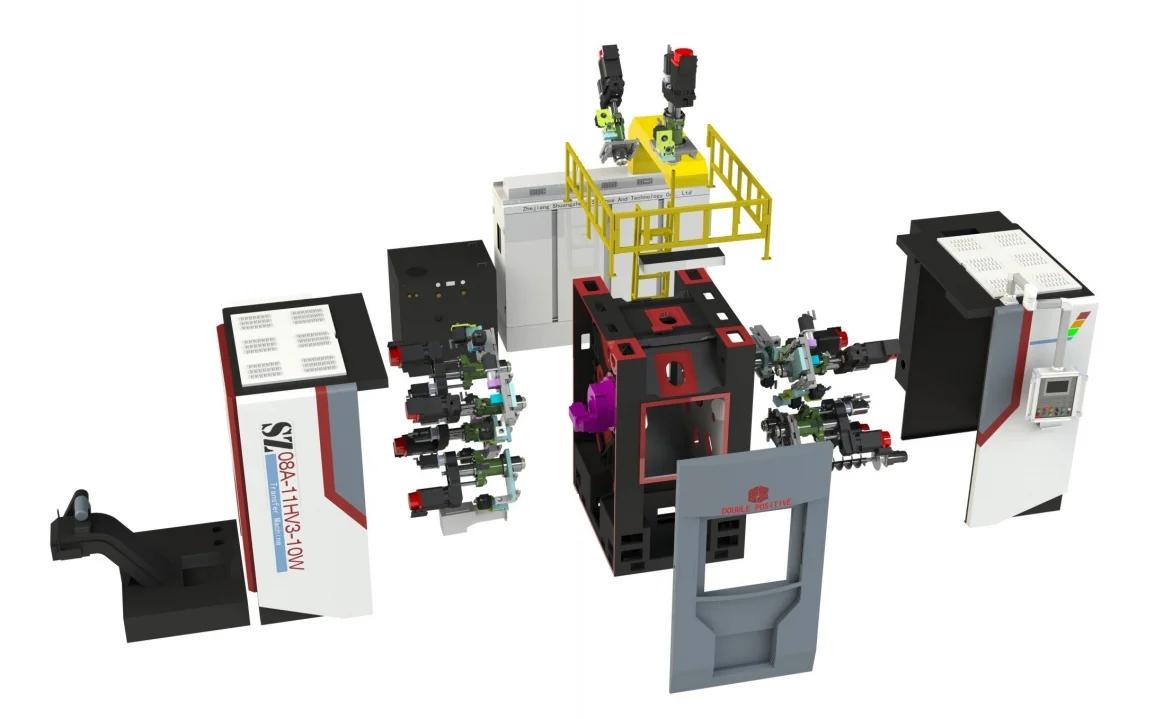

Disc type special machine tool at https://www.zjshuangzheng.com/Disc-Type-Special-Machine.html