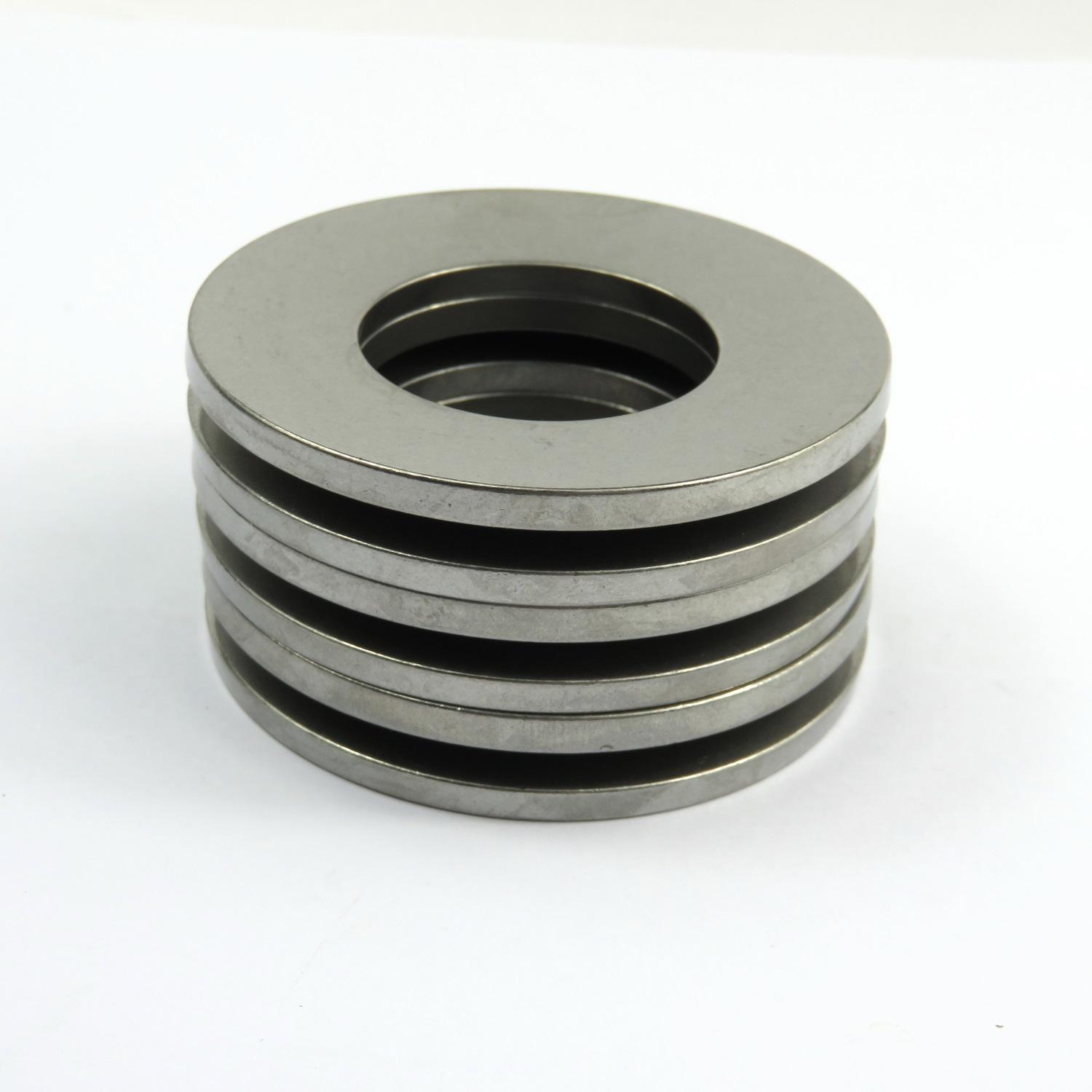

The analysis of four key materials used for disc springs (Belleville washers) based on their properties and application suitability

1.51CrV4: A cost-effective chromium-vanadium alloy steel offering high tensile strength, fatigue resistance, and moderate corrosion resistance. Commonly used in automotive, industrial machinery, and clamping systems but requires surface treatments in corrosive environments.

2.17-7 PH: Precipitation-hardened stainless steel known for excellent corrosion resistance, high strength, and fatigue resistance. Used in aerospace, defense, and marine applications due to its ability to perform in harsh and high-temperature conditions.

3.SUS 304: Austenitic stainless steel with outstanding corrosion resistance and good formability. Suitable for food processing, medical applications, and low-load systems where durability in moist or sanitary environments is critical.

4.Inconel 718: A nickel-chromium super-alloy with exceptional strength, heat, and corrosion resistance. Ideal for extreme environments like aerospace engines, turbines, and oil and gas equipment.

1.51CrV4: A cost-effective chromium-vanadium alloy steel offering high tensile strength, fatigue resistance, and moderate corrosion resistance. Commonly used in automotive, industrial machinery, and clamping systems but requires surface treatments in corrosive environments.

2.17-7 PH: Precipitation-hardened stainless steel known for excellent corrosion resistance, high strength, and fatigue resistance. Used in aerospace, defense, and marine applications due to its ability to perform in harsh and high-temperature conditions.

3.SUS 304: Austenitic stainless steel with outstanding corrosion resistance and good formability. Suitable for food processing, medical applications, and low-load systems where durability in moist or sanitary environments is critical.

4.Inconel 718: A nickel-chromium super-alloy with exceptional strength, heat, and corrosion resistance. Ideal for extreme environments like aerospace engines, turbines, and oil and gas equipment.

The analysis of four key materials used for disc springs (Belleville washers) based on their properties and application suitability

1.51CrV4: A cost-effective chromium-vanadium alloy steel offering high tensile strength, fatigue resistance, and moderate corrosion resistance. Commonly used in automotive, industrial machinery, and clamping systems but requires surface treatments in corrosive environments.

2.17-7 PH: Precipitation-hardened stainless steel known for excellent corrosion resistance, high strength, and fatigue resistance. Used in aerospace, defense, and marine applications due to its ability to perform in harsh and high-temperature conditions.

3.SUS 304: Austenitic stainless steel with outstanding corrosion resistance and good formability. Suitable for food processing, medical applications, and low-load systems where durability in moist or sanitary environments is critical.

4.Inconel 718: A nickel-chromium super-alloy with exceptional strength, heat, and corrosion resistance. Ideal for extreme environments like aerospace engines, turbines, and oil and gas equipment.

0 Komentarze

0 Udostępnienia